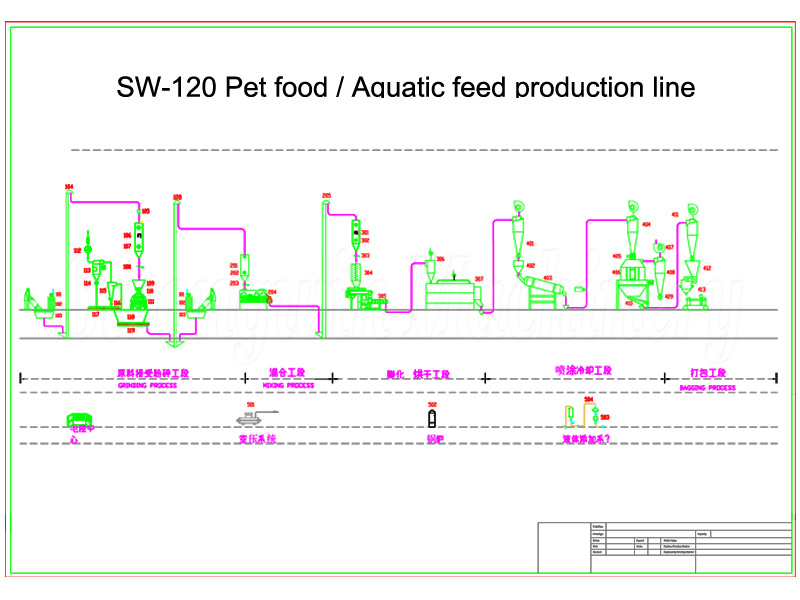

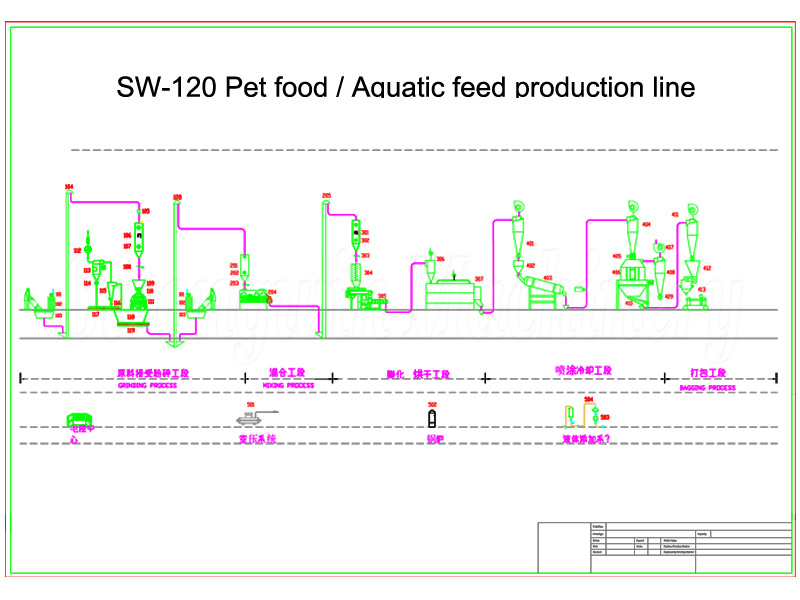

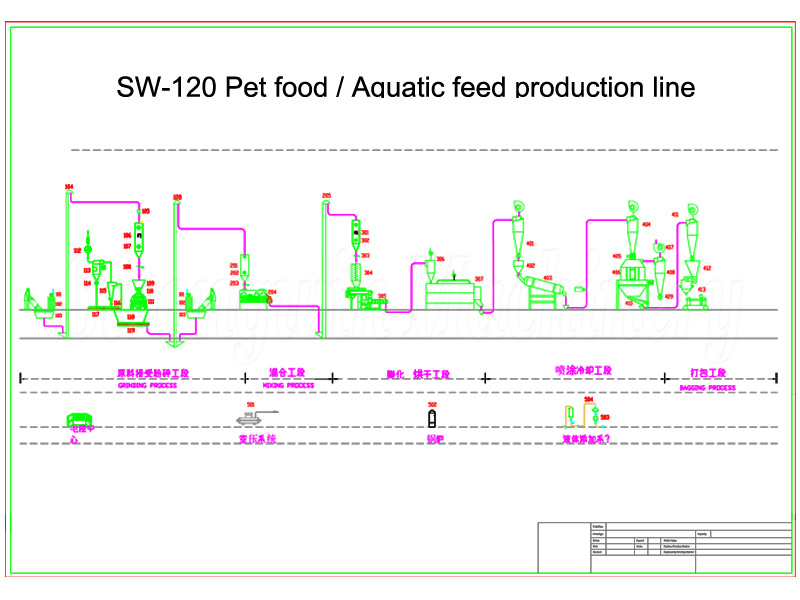

Raw material receiving and cleaning work section: This section of the granularity of this section and the separation of the cleaning of the powder and the cleaning of the powder, the dust removal alone, the dust removal effect is good.

Ultra-micro crushing section: Because the patch machine has high requirements for the fineness of the raw materials, generally 60-120 mesh, this section uses ultra-micro crushing machines, the pieces are equipped with two crushed warehouses, which can be carried out of the material to reduce the material to reduce the ultra-ultra-ultra-supernatural The micro crusher should replace the air rotation time, using wind transportation materials, configured brake dragon, pulse dust collector, and crushing fineness can be adjusted.

Expansion section: This section uses two twin-screw expansion machines, with one expansion bin above each machine. The expansion bin is designed as a circular bin and equipped with a disc feeder to prevent material arching and smooth discharge.

Spray packaging section: This section uses two sets of drum grease spraying equipment, which are equipped with pneumatic tees before entering the equipment. Depending on different formula requirements, the finished particles can be selected for oil spraying. Post spraying solves the problem of not adding too much oil to the materials in the early stage, which cannot meet the requirements of oil addition. Moreover, the feed after spraying has a good appearance, strong palatability, and strong nutritional value. The materials sprayed with oil are screened and packaged after being cooled by a pendulum cooler.

Auxiliary section: Dust removal system, dust removal at the packaging port, improving the working environment for workers; Oil and water addition system to improve feed palatability.

Floating fish feed plant is applicable to produce feed pellets for pets, ornamental fish, pond-fish, and marine fish, such as catfish, shrimps, crabs etc.

After installation and adjustment, we will train our customers to work how to operate;

Training workers on how to maintain and protect.

According to features, we will make complete maintenance rules for you, containing how to maintain, when to maintain, and who maintain

Our company after-sale department will call you at regular intervals, ask if maintain and give advice.