The client discovered our company online while urgently seeking to upgrade their production system with a high-efficiency, stable, and flexible puffing equipment solution.

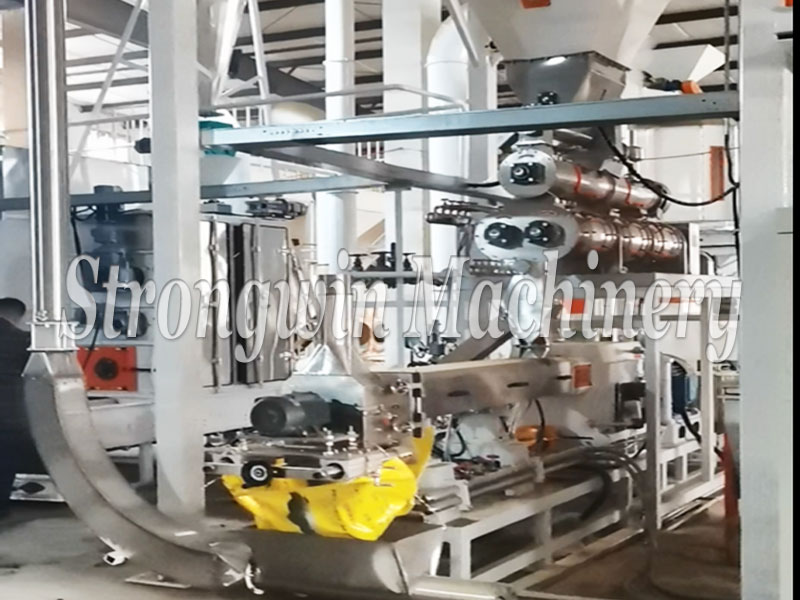

To address their needs, we delivered a fully tailored puffing production line featuring:

✅ High Output: Achieves 1 ton/hour floating feed production, resolving urgent capacity shortages.

✅ Superior Quality: Ensures an over 98% expansion rate with uniform, dense pellets that float longer.

✅ Adaptive Parameters: Adjustable processing settings (e.g., for protein content and moisture) to support the R&D of functional feeds.

✅ Durable Construction: Critical components made of 304 stainless steel—corrosion-resistant, easy to clean, and compliant with hygiene standards, extending equipment lifespan while cutting maintenance costs.

Smooth Implementation: Completed installation and commissioning within schedule.

Client Feedback: “The results exceeded expectations! The stainless steel design ensures durability and consistent output. The customizable parameters have been invaluable for our new product development.”

Competitive Edge: Enabled rapid market response and future-ready production flexibility.

Whether you’re a startup or an industry leader, we provide end-to-end solutions—from single machines to complete plant planning—to deliver high-efficiency, durable puffing production lines tailored to your needs. Seize market opportunities with confidence!